Fasikon Drilling Tools: Why High-Performance DTH Hammers & Bits Reduce Your Total Drilling Cost

Why High-Performance DTH Hammers & Bits Matter for Cost-Effective Drilling

—Technical Insights from Fasikon Drilling Tools

In mining, water well, geothermal, and construction drilling, many factors influence drilling efficiency and project cost: machine horsepower, geological hardness, operator experience, etc.

But in field practice, the most decisive factor is the performance of the DTH Hammer and DTH Bit.

After analyzing more than 3,000 field cases, Fasikon’s engineering team came to a clear conclusion:

With the same drilling rig and air compressor, a high-performance DTH hammer and bit can reduce your overall drilling cost by 15%–35%.

This article explains the technical reasons behind it.

1. Impact Energy Efficiency Defines Penetration Rate

The core metric of DTH hammer performance is impact energy transfer efficiency.

Typical market hammers deliver 65%–75% energy transfer.

Fasikon’s latest hammer structure reaches:

⭐ Up to 82% impact energy efficiency

This translates to:

-

Higher instantaneous rock-breaking efficiency

-

Higher impact frequency

-

Faster average penetration rate

📌 Real Field Comparison

| Equipment | Penetration Rate | Result |

|---|---|---|

| Standard 6″ DTH Hammer | 0.9–1.2 m/min | Normal performance |

| Fasikon 6″ Hammer | 1.3–1.7 m/min | Up to 35% faster |

2. Bit Life Determines Long-Term Consumable Cost

Many drilling companies overlook one key fact:

A drill bit is not a one-time cost—it’s a long-term operational expense.

Thanks to premium alloy steel, heat treatment, and high-grade tungsten carbide buttons, Fasikon DTH bits offer:

⭐ 1.5–2× the service life of standard market bits

The optimized flushing groove design also ensures longer carbide sharpness and better heat dissipation.

3. Air Consumption Directly Affects Fuel Usage

Air compressors are the most expensive machines to run on a drilling site.

With the same pressure and airflow, Fasikon’s optimized internal structure improves air utilization:

⭐ 12%–18% higher air efficiency

Which translates into:

-

Lower compressor load

-

Reduced diesel consumption

-

Lower operating temperature and longer compressor life

For high-hour drilling operations, this can save thousands of dollars annually.

4. Longer Hammer Life = Less Downtime

The internal components of Fasikon hammers are reinforced to deliver:

⭐ 8,000–12,000 meters of total life (comparable to premium international brands)

This means:

-

Fewer breakdowns

-

Fewer disassemblies

-

Less unplanned downtime

In mining operations, downtime losses often exceed the cost of replacement parts.

5. Core Technical Advantages of Fasikon DTH Tools

🔧 1. Ultra-Hardened Internal Cylinder

Minimizes wear and preserves energy output.

🔧 2. Optimized Airflow System

Reduces energy loss and increases impact frequency.

🔧 3. Full Compatibility

Fully compatible with Atlas Copco, Sandvik, Numa, Halco, and other standard shanks.

🔧 4. Field-Proven Durable Structure

Trusted by drilling contractors in Russia, Central Asia, Africa, and South America.

6. High-Performance DTH Tools Are Not More Expensive—They Save You Money

Many procurement managers ask:

“Why do some hammers look cheaper in the beginning?”

Because low-cost hammers cost more in the long run.

A Fasikon high-performance hammer and bit will reduce:

-

Drilling time

-

Diesel consumption

-

Bit replacement frequency

-

Rig downtime

-

Maintenance cost

When considering the full project economics:

Fasikon is the more stable and cost-effective choice.

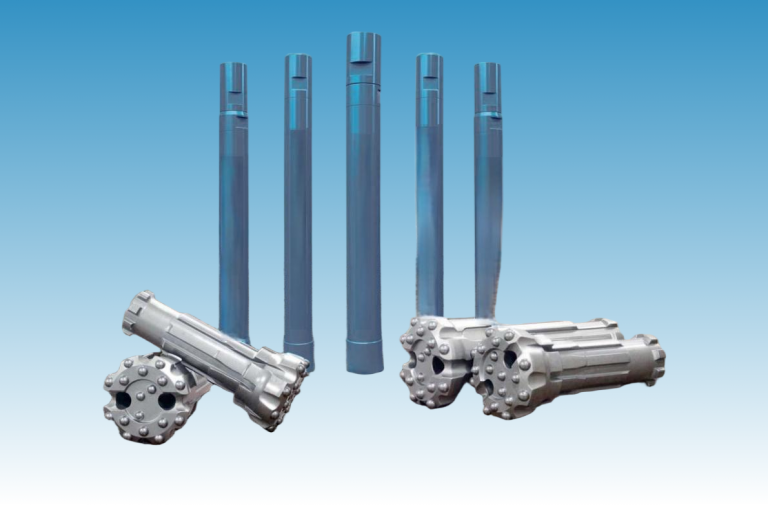

⭐ Fasikon Drilling Tools — International-Grade Performance With Better Pricing

We supply:

-

DTH Hammers (3″–12″)

-

DTH Bits (Button/Ballistic)

-

Shank Adapters

-

Couplings & Sleeves

-

Drill Rods

-

RC Drilling Consumables

-

OEM / Custom solutions

For technical consultation, specifications, or quotations:

📧 Email: kevin@fasikon.com

📱 WhatsApp: +8617722505240

🌐 Website: fasikon.com