How to Improve Rock Drilling Efficiency with the Right DTH Tools

A Practical Guide from Fasikon Drilling Tools

In mining, quarrying, water well drilling, and construction projects, drilling efficiency directly determines project cost and timeline. Selecting the right drilling tools is not just a technical decision — it is a strategic one.

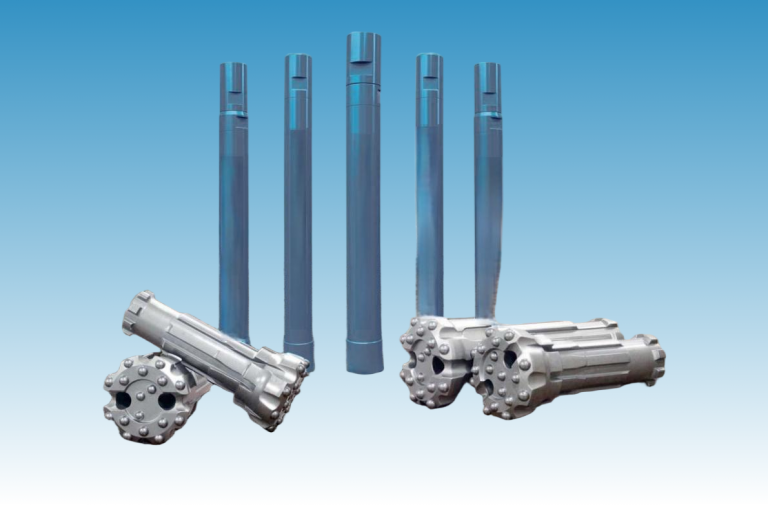

At Fasikon Drilling Tools, we work closely with drilling contractors and distributors worldwide to provide reliable, high-performance DTH hammers and drill bits designed for demanding rock conditions. This article explains how the right DTH tools can significantly improve drilling efficiency and reduce operational costs.

What Is DTH Drilling and Why Does It Matter?

DTH (Down-The-Hole) drilling uses a pneumatic hammer located directly behind the drill bit. Compressed air powers the hammer, delivering high-impact energy straight to the rock face.

Compared with traditional rotary drilling, DTH drilling offers:

-

Faster penetration rates in hard rock

-

Better hole straightness

-

Lower energy loss

-

Improved bit life

This makes DTH drilling ideal for hard and abrasive formations, such as granite, basalt, limestone, and quartzite.

Key Factors That Affect DTH Drilling Efficiency

Many drilling problems are not caused by the rig or air compressor, but by mismatched or low-quality drilling tools. The following factors play a critical role:

1. Hammer Design and Air Efficiency

A well-designed DTH hammer ensures:

-

Stable piston movement

-

Efficient air distribution

-

Reduced internal wear

Fasikon DTH hammers are engineered to maintain consistent impact energy, even under high-pressure working conditions.

2. Drill Bit Quality and Button Layout

The drill bit directly contacts the rock, making it the most critical wear component.

High-quality DTH bits should feature:

-

Premium alloy steel bodies

-

High-grade tungsten carbide buttons

-

Optimized button geometry for different rock formations

Fasikon DTH drill bits are designed for maximum penetration with controlled wear, helping reduce downtime and replacement frequency.

3. Compatibility with Global Standards

Interchangeability is essential for international drilling operations.

Fasikon tools are compatible with major industry standards, including:

-

DHD series

-

QL series

-

Mission series

-

SD series

This ensures smooth replacement and easy integration with existing equipment.

Common Drilling Problems and How to Avoid Them

| Problem | Possible Cause | Recommended Solution |

|---|---|---|

| Low penetration rate | Incorrect bit design | Match bit face to rock type |

| Excessive bit wear | Poor carbide quality | Use premium-grade buttons |

| Air leakage | Hammer sealing issues | Choose precision-machined hammers |

| Hole deviation | Tool imbalance | Use properly matched hammer & bit |

Choosing the correct tool combination can increase drilling efficiency by 20–30% in real working conditions.

Why Choose Fasikon Drilling Tools?

Fasikon is committed to providing cost-effective drilling solutions without compromising quality.

Our advantages include:

-

✔ Strict quality control and heat treatment processes

-

✔ Stable performance in hard rock environments

-

✔ Competitive pricing for distributors and contractors

-

✔ Technical support for tool selection and application

-

✔ Custom solutions based on working conditions

Whether you are working on mining, quarrying, water well, or exploration drilling, Fasikon offers tools you can rely on.

Applications of Fasikon DTH Tools

Our products are widely used in:

-

Mining and exploration drilling

-

Water well and geothermal drilling

-

Quarry and blasting operations

-

Construction and foundation drilling

Each application has different requirements, and our team helps customers choose the most suitable hammer and bit configuration.

Final Thoughts: Efficiency Starts with the Right Tools

Improving drilling efficiency is not only about higher air pressure or larger rigs — it starts with well-matched, high-quality drilling tools.

By choosing reliable DTH hammers and drill bits from Fasikon, drilling professionals can:

-

Reduce operating costs

-

Extend tool service life

-

Improve penetration rates

-

Increase overall project profitability

📩 Contact Fasikon Drilling Tools

Email: kevin@fasikon.com

WhatsApp: +86 17722505240

🌐 Learn more at: www.fasikon.com