Rotary Tricone Bits: Design, Types, and How to Select the Right Bit for Drilling Applications

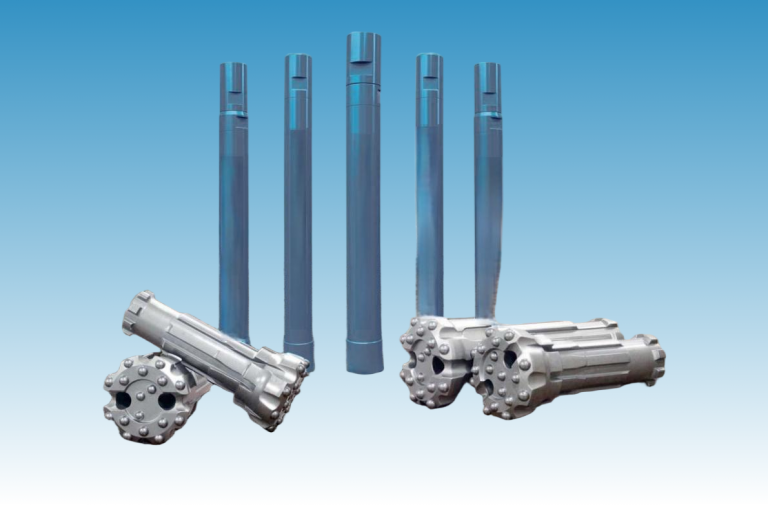

Rotary Tricone Bits are one of the most widely used drilling tools in oil & gas drilling, water well drilling, mining, and geological exploration. Thanks to their versatile design and strong adaptability to different formations, tricone bits remain a cost-effective and reliable solution for rotary drilling operations.

This article explains the design structure, main types, technical features, and selection guidelines of rotary tricone bits, helping drilling engineers and buyers choose the right bit for their applications.

What Is a Rotary Tricone Bit?

A Rotary Tricone Bit is a rock drilling bit composed of three rotating cones, each mounted with cutting elements that crush and shear the formation under weight on bit (WOB) and rotational force. Tricone bits are suitable for drilling soft, medium, and hard formations, depending on cutting structure and bearing design.

Main applications include:

-

Oil & gas drilling

-

Water well drilling

-

Mining and quarry drilling

-

Geothermal and geological exploration

Structure of Rotary Tricone Bits

A standard rotary tricone bit consists of the following key components:

Cones and Cutting Structure

-

Steel Tooth (Milled Tooth) Tricone Bits

Designed for soft to medium formations such as clay, shale, and soft limestone. -

TCI (Tungsten Carbide Insert) Tricone Bits

Suitable for medium to hard and abrasive formations with superior wear resistance.

Bearing System

-

Roller bearing

-

Journal bearing

-

Sealed journal bearing with grease reservoir and O-ring seals

A high-quality bearing system directly affects bit life and drilling stability.

Nozzle and Hydraulic System

Optimized nozzle design ensures efficient cuttings removal, cooling, and prevention of bit balling.

Shirttail and Gauge Protection

Advanced hardfacing materials are applied to critical wear areas to improve durability in abrasive formations.

Types of Rotary Tricone Bits by Formation

Tricone bits are commonly classified according to IADC codes, which define formation hardness and cutting structure:

-

Soft Formation Tricone Bits (IADC 117–127)

Wide tooth spacing, high penetration rate. -

Medium Formation Tricone Bits (IADC 437–537)

Balanced design for limestone, sandstone, and mixed formations. -

Hard Formation Tricone Bits (IADC 637–837)

Dense TCI layout, sealed bearings, excellent wear resistance.

Choosing the correct IADC code is critical to achieving optimal drilling performance.

Key Performance Factors of Tricone Bits

Weight on Bit (WOB) and RPM

Improper drilling parameters often lead to premature wear or bearing failure. Tricone bits require a balanced combination of WOB and rotation speed.

Formation Matching

Mismatch between bit design and formation hardness can result in low rate of penetration (ROP) and shortened service life.

Hydraulics and Mud Flow

Efficient bottom-hole cleaning improves ROP and reduces the risk of cone clogging and uneven wear.

Common Technical Problems in Tricone Bit Drilling

Uneven Tooth or Insert Wear

-

Incorrect WOB or RPM

-

Poor hydraulics

-

Formation changes

Bearing Failure

-

Excessive load

-

Seal damage

-

High operating temperature

Low Penetration Rate

-

Worn cutting structure

-

Inappropriate bit selection

-

Insufficient cleaning

Understanding these issues helps reduce drilling costs and improve overall efficiency.

How to Select the Right Rotary Tricone Bit

When selecting a tricone bit, consider:

-

Formation type and abrasiveness

-

Drilling depth and temperature

-

Rig capability (WOB & RPM)

-

Drilling fluid type and flow rate

A properly selected tricone bit can significantly reduce cost per meter and minimize downtime.

Why Choose Fasikon Rotary Tricone Bits?

At Fasikon Drilling Tools, we supply rotary tricone bits designed for:

-

Stable penetration rate

-

Long bearing life

-

Reliable performance in global drilling conditions

Our tricone bits are widely used in mining, water well, and oilfield drilling projects, with consistent quality and competitive lead times.

Conclusion

Rotary Tricone Bits continue to play a vital role in modern drilling operations. By understanding bit structure, types, and selection principles, drilling professionals can achieve higher efficiency and longer bit life.

If you are looking for reliable rotary tricone bit suppliers, Fasikon is ready to support your drilling projects with application-oriented solutions.